Bridge KBK Cranes

♦Comparation of KBK CRANE

| TYPE |

VALUE |

| Main beam quantity |

1 set |

| Main beam length |

4500mm | Customizable |

| Rail length |

10000mm | Customizable |

| Tavelling method |

electric |

| Tavelling speed |

0-20 m/min |

| Lifting capacity |

3000kg | Customizable |

| Lifting speed |

3.3m/min |

|

|

|

|

|

| Lifting height |

4m | Customizable |

| Track power supply method |

tow cable |

| Main beam power supply method |

tow cable |

| Operating method |

ground control +remote control |

| PowerDD |

380V/50HZ |

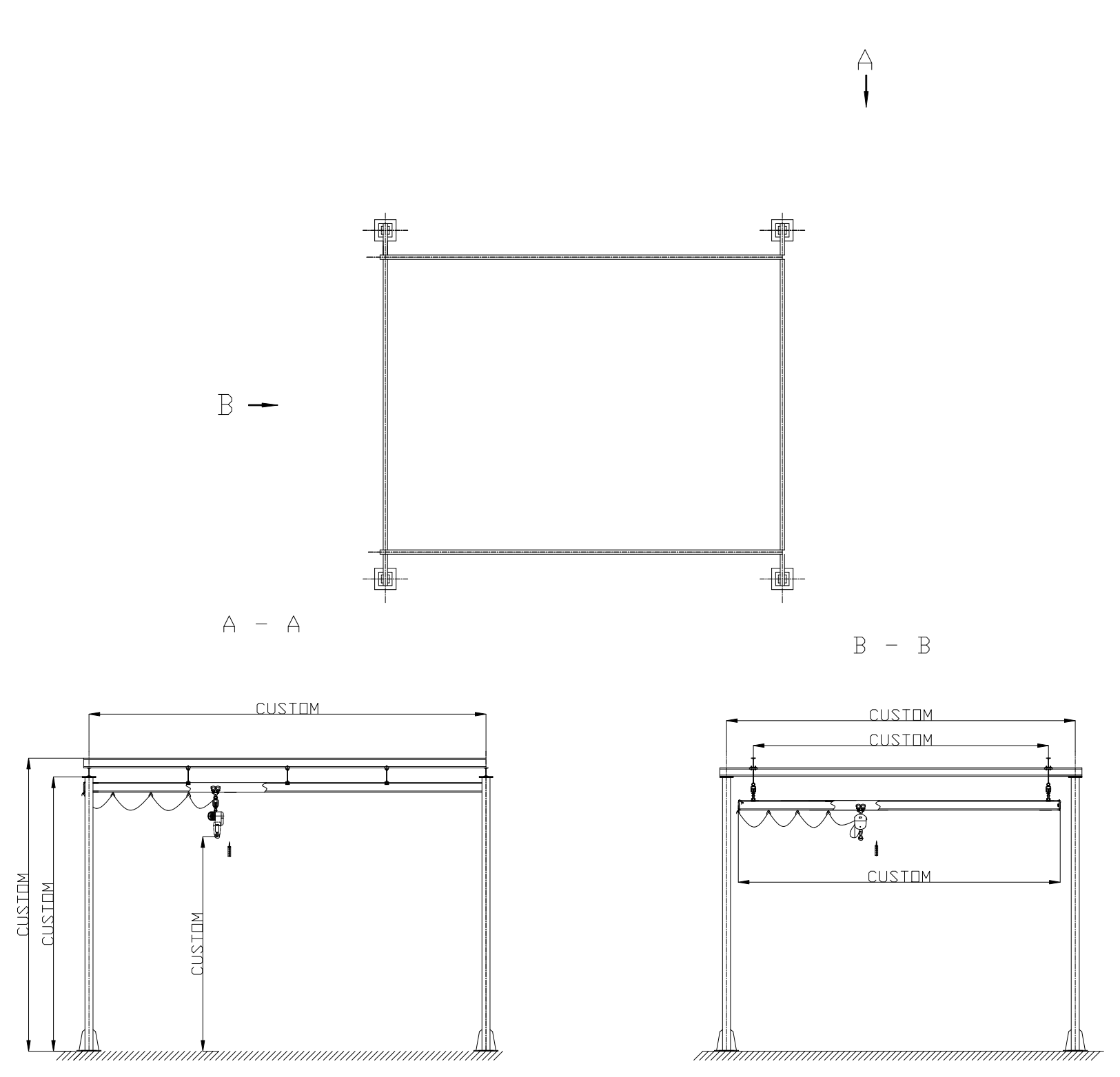

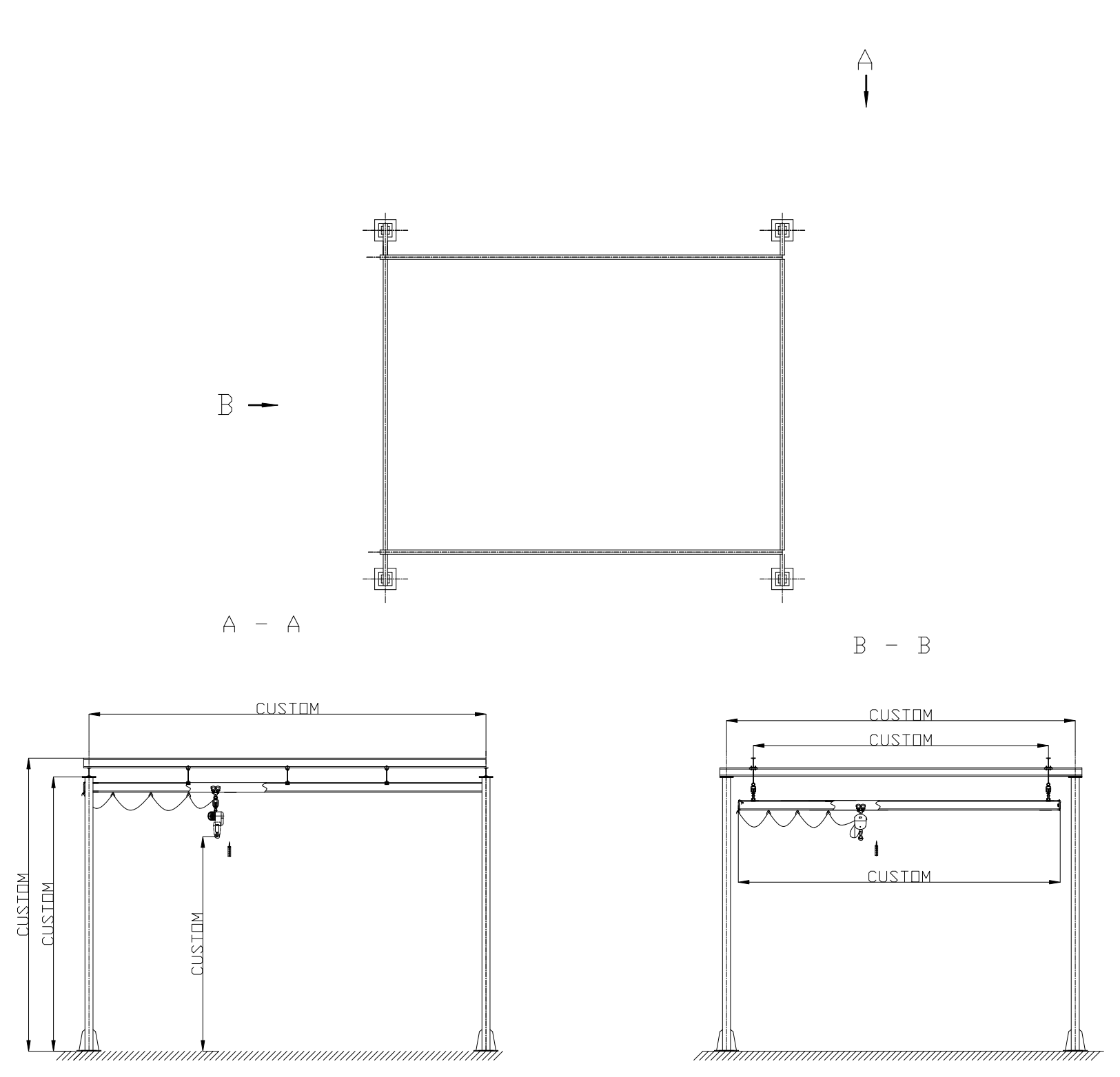

Hoisting equipment used to lift materials horizontally over workshops, warehouses and stockyards. Because its two ends are located on tall cement columns or metal supports, the bridge of the bridge crane runs longitudinally along the tracks laid on the elevated structures on both sides, making full use of the space under the bridge to lift materials without being hindered by ground equipment.

♦Advantages of kbk cranes:

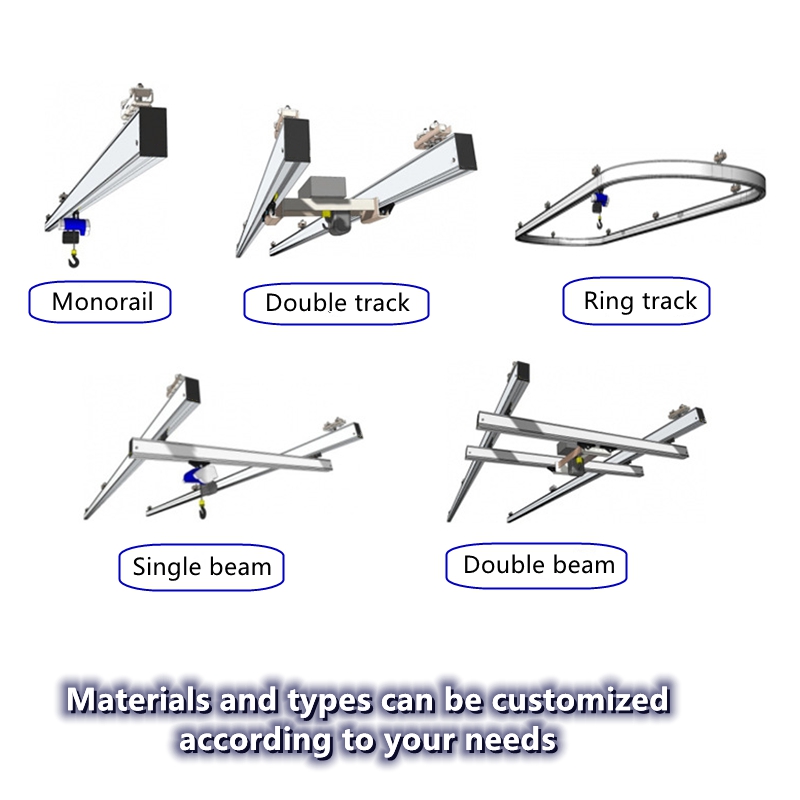

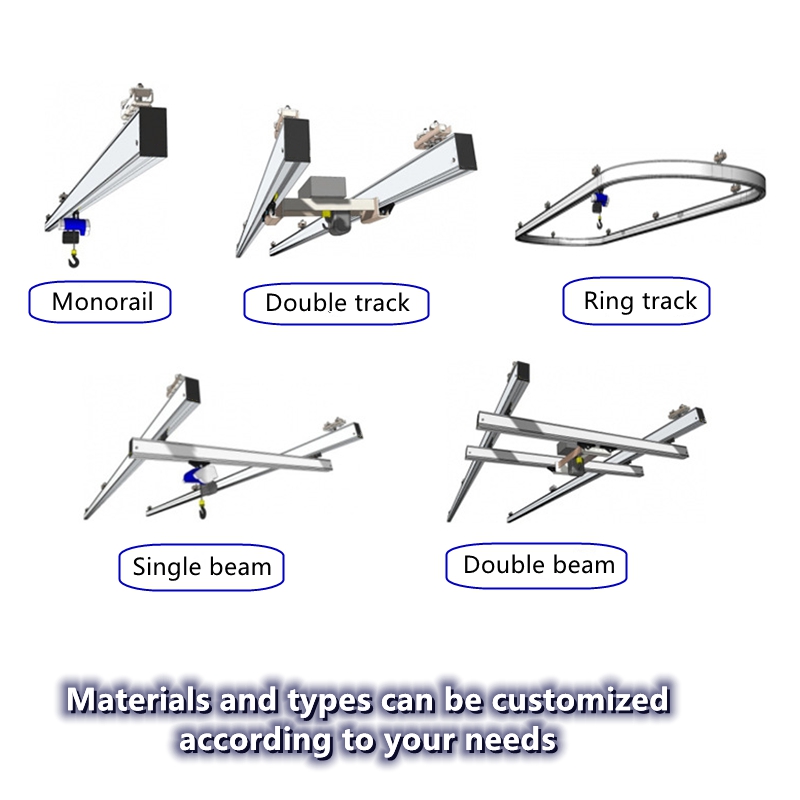

The design of the KBK crane allows the user to configure flexibly according to the actual needs. Its tracks can be freely arranged to adapt to different working environments and space constraints. This flexibility allows KBK cranes to play an important role in a variety of industrial situations, such as workshop production lines, assembly lines, etc.

♦Benefits of an KBK Crane:

1. Profile rail trolley: non-stamping parts, high strength and long life

2.Lifting device: high precision, intelligent, speed controllable

3. Electric drive: motor drive, variable frequency speed regulation, smooth operation

4. Cable towing system: independent module, easy to disassemble and assemble, increasing the actual operating working area

♦Why choose us

Beginning in 2003, Dingya crane engineers began to continuously try the application of frequency converters on cranes. It has been continuously verified for 18 years and has been selected from many brands and different models of inverters at home and abroad. Today, Dingya has been very mature in technology for variable frequency cranes driven by frequency converters for weightless lifting. Dingya has now exported to Poland, Ireland, the United Arab Emirates, Israel, Russia, Belarus, the United States, Saudi Arabia, Uzbekistan, Côte d’Ivoire, Argentina, Palestine, Chile, Canada, Italy, Colombia, Mexico, Spain, Armenia and many other countries in Southeast Asia (Indonesia, Myanmar, Philippines, Laos, Myanmar, Cambodia, Vietnam, India , Mongolia, South Korea)…

"Let more users use good cranes" is also Dingya's consistent philosophy. We sincerely hope to help and serve more users!

Senior Engineers Provide Technology - More Professional

◊Senior Electrical Engineer

◊Lifting plan planning expert

◊Senior Mechanical Engineer

Our senior engineers will work together to solve your crane questions, both pre-purchase and post-installation.

Contact Us

Contact Us